our approach

Welcome inside our factories. We document every build from the first fixture to the final sign off so you can see exactly how your parts come to life. Carbon is produced in both wet lay and dry carbon prepreg, exhausts are built and valve tested, wheels are machined from 6061 T6 and finished to spec, intakes are made in titanium carbon and silicone, and headlights are assembled sealed aimed and tested before they leave. Below, walk the line with us through the real stations and the people who run them, and get a clear look at each stage.

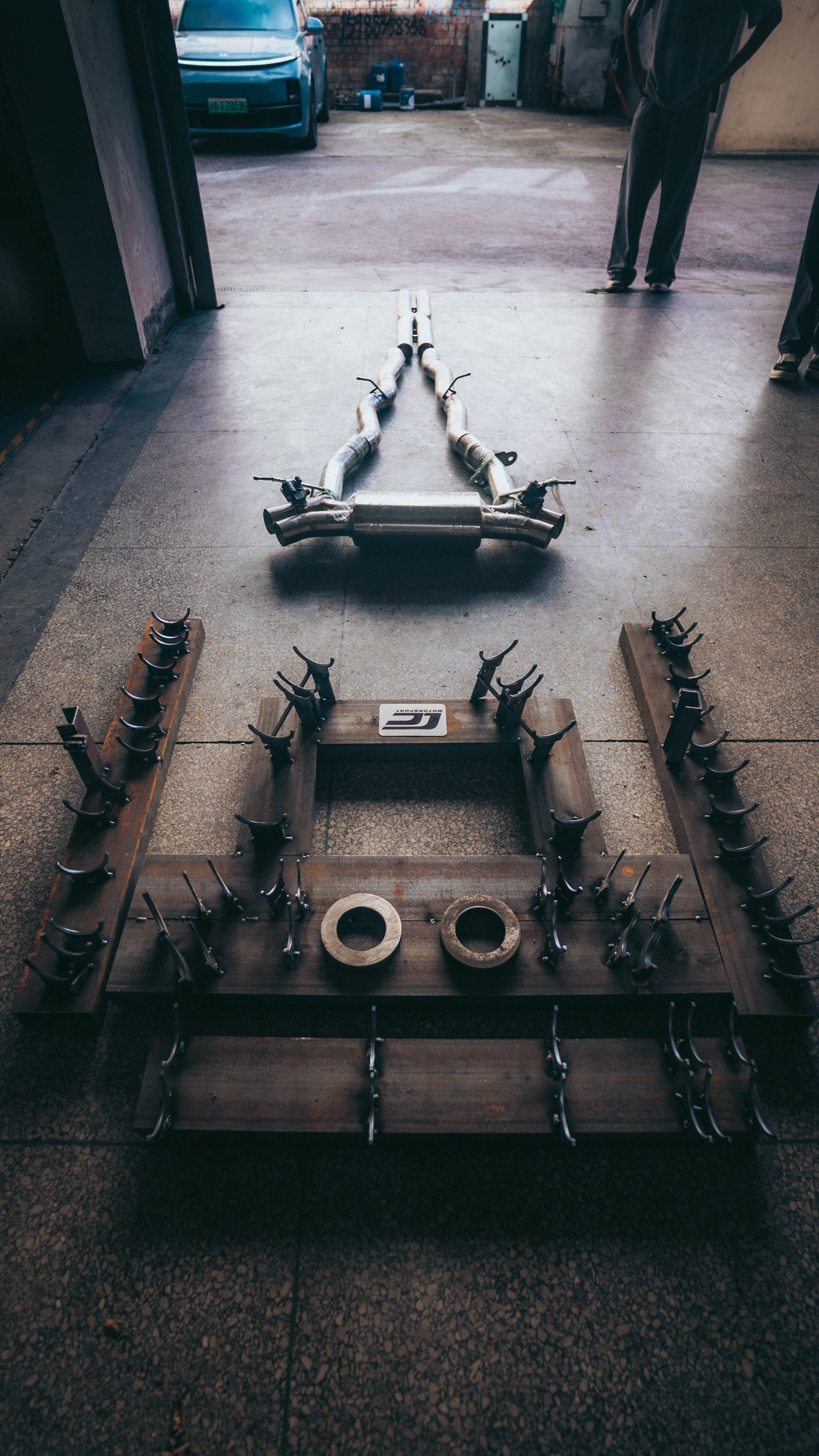

Exhausts

Built on chassis fixtures so hangers and flanges land exactly where they should. We offer T304 stainless and Grade 5 titanium systems, all valved with controllers. Titanium systems are hand burned for that color you expect, and we now offer a gold electroplated stainless finish. Most titanium specs are made to order and run in small batches for consistency.

wheels

Built for your chassis and how you drive. Choose monoblock, two piece, three piece, or beadlock with an optional carbon ring and CC center caps. We cut width and offset for the stance you want without rub and with room for big brake kits, then finish them your way in silver, bronze, gunmetal, black, chrome, or custom. Sets are made to order with a hub centric fit and the right hardware, protected in transit so they arrive ready to bolt on.

Carbon Fiber

Built on factory mounting points so everything lines up clean and stays put. We make OEM plus aero that actually looks right on the car—front lips, diffusers, side skirts, mirror caps, and spoilers—with straight weave at the body lines, crisp edges, and a UV stable clear in gloss or matte. Each piece gets a quick test fit, includes the hardware you need when applicable, and ships protected so it arrives ready to install.

front mount intakes

We route cool air forward with solid brackets and sensor placement that plays nice with the ECU. Choose silicone, carbon, or titanium runners; high-flow filters are supplied with rain bags for weather protection. Each kit is bench-checked and test-fit before it ships.

headlights

Our headlights are built, sealed, and tested in house so they look factory and perform better. We engineer the DRL signature and turn signal function around the car’s electrical system, then design and produce the control modules and harnesses to talk cleanly to the vehicle without errors. Each set is bench tested for output, DRL and blinker behavior, and power draw, then aimed, weather tested for moisture intrusion, and verified on a chassis jig before it ships. If coding is required for your platform, we note it clearly so the install is straightforward.

QC & Packaging

Fit and Finish

Surfaces and edges inspected, mounting points confirmed, and a quick test fit on a fixture or shop car. Anything off is reworked or rejected.

Functional Test

Exhausts get valve cycling, leak and tip alignment checks. Headlights power up on a switchboard and aim is verified. Intakes and wheels get sensor, bracket, hub fit, and big brake clearance checks.

Pack and Protect

Hardware is bagged by chassis, edges are foamed, parts are wrapped and boxed tight, carbon is double boxed, labels are applied, and tracking is issued. CenCal Package Protection is recommended.

made-to-order timeline

Stage 01

Design

Your spec is locked. Final renders and drawings are approved, logo plate artwork is set, and the programs are queued. Materials and fixtures are staged so exhausts, wheels, and other made-to-order parts move straight into production.

Stage 02

cut & prep

Stainless is cut for exhaust sections, titanium is pie-cut and cleaned for color work, and wheel forgings are staged. CNC machines warm up for faces, pockets, and logo plates while jigs and purge setups are laid out so each station is ready.

Stage 03

Machine, Form, and Weld

Wheel faces and details are machined to spec. Stainless exhaust sections are fit on chassis fixtures and TIG welded. Titanium sections are tacked, purged, and welded clean so the system is ready for finish and final assembly.

Stage 04

Finish and Assemble

Titanium gets its signature heat color. Stainless can be finished in standard polish or our gold finish. Exhausts receive valve actuators and controllers. Wheels get hardware test-fit, beadlock rings torqued down, carbon rings fitted when chosen, and CC center caps installed.

Stage 05

Function & Fit Checks

Exhaust valves cycle and tips are aligned on a chassis fixture with clearance checks. Wheels are verified for hub fit, bolt pattern, and big-brake clearance. Intakes get bracket and sensor placement checks. Headlights are powered on a switchboard to verify DRLs and turn signals, then aimed and sealed.

Stage 06

pack & ship

Final visual inspection, then hardware is bagged and labeled by chassis. Edges are protected with foam, carbon is double-boxed, cartons are sealed and labeled, and tracking is sent when your order leaves. CenCal Package Protection is available at checkout.

Factory Built

Produced in our factories with documented steps and fixtures mapped to OEM mounting points.

Fitment Verified

Key dimensions checked and a quick test fit on a fixture or shop car where it matters.

QC Tested

Valves cycle, lighting is bench tested, and brackets, sensors, and clearances are verified per part.

Prep & Package

Hardware bagged by chassis, edges foamed, carbon double boxed, tracking issued on dispatch.

Factory floor

ready?

You’ve seen how we build—now make it yours. Pick your chassis, shop the parts, or start a wheel spec. In-stock ships fast; made-to-order timelines are shown on each product page.